Sensors

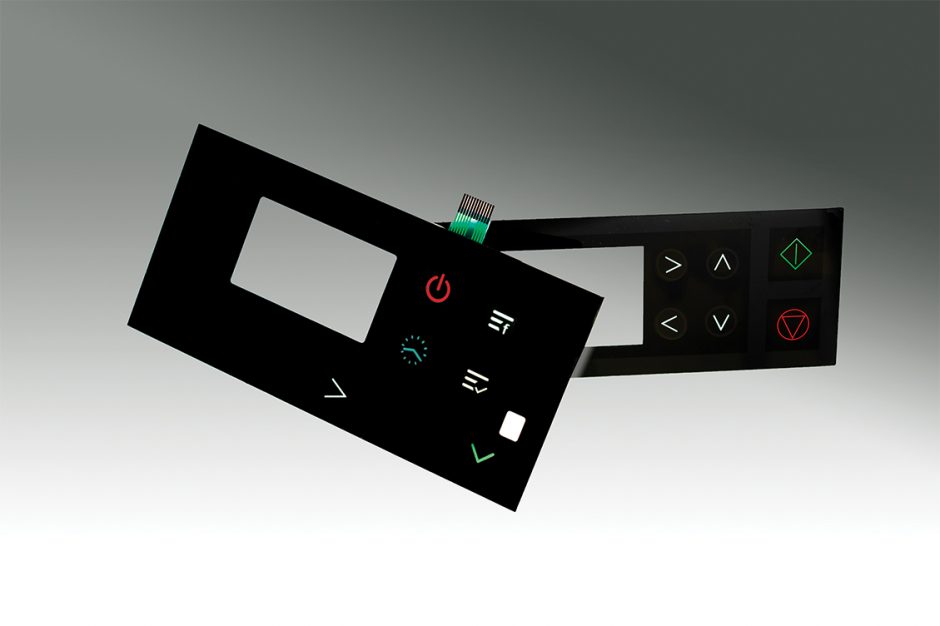

The sensor is the interface element between the frontpiece and electronic board of a capacitive system.

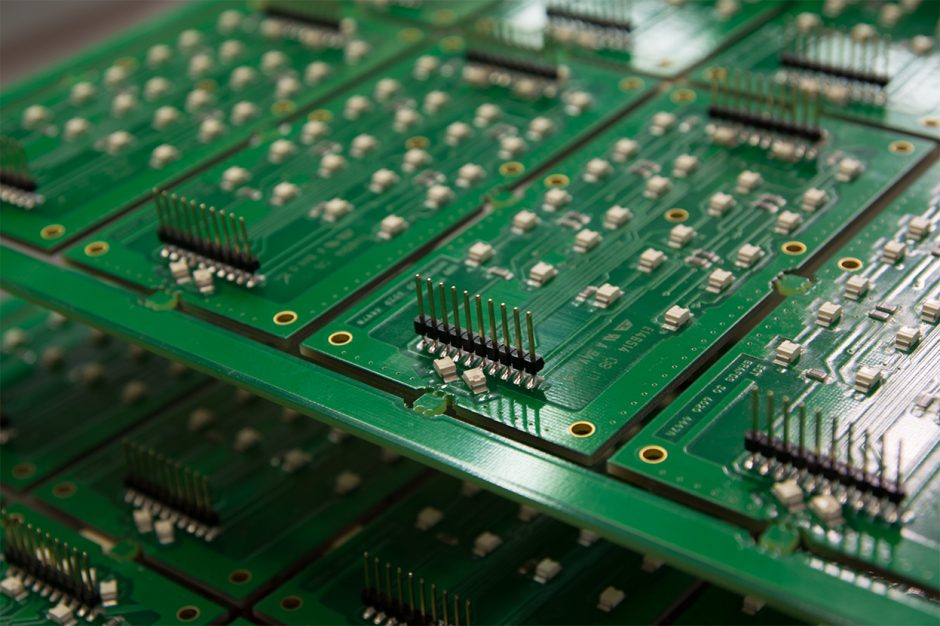

It is made of polyester film using the latest technologies for both conductive inks (nanotechnologies) and printing techniques that enable the creation of thin conductive tracks only a few microns thick.

All the sensors built by OXI Group are tested with special equipment that verify their perfect functioning, guaranteeing the capacitive system the highest quality performance.